Telo wants to deliver the world’s most efficient electric truck

Why do pickups have to be so huge, and where are the lean, efficient, manageably sized electric trucks for the city?

Emerging from stealth mode Tuesday, California-based Telo Trucks is revealing its thought-provoking answer to that—in the form of an electric pickup that it claims will have all the cab and bed space of a Toyota Tacoma, with comparable payload and towing capability.

And the length of that vehicle? The same 152 inches as a two-door Mini Cooper SE.

Telo truck vs Mini Cooper SE

With an overall length the size of some of the smallest U.S.-market cars, and an overall width and height of 73 and 66 inches and a height of 66 inches that compare to many compact crossovers, Telo manages space for five, four full-size doors, and a five-foot bed that’s also five feet wide and 18 inches deep.

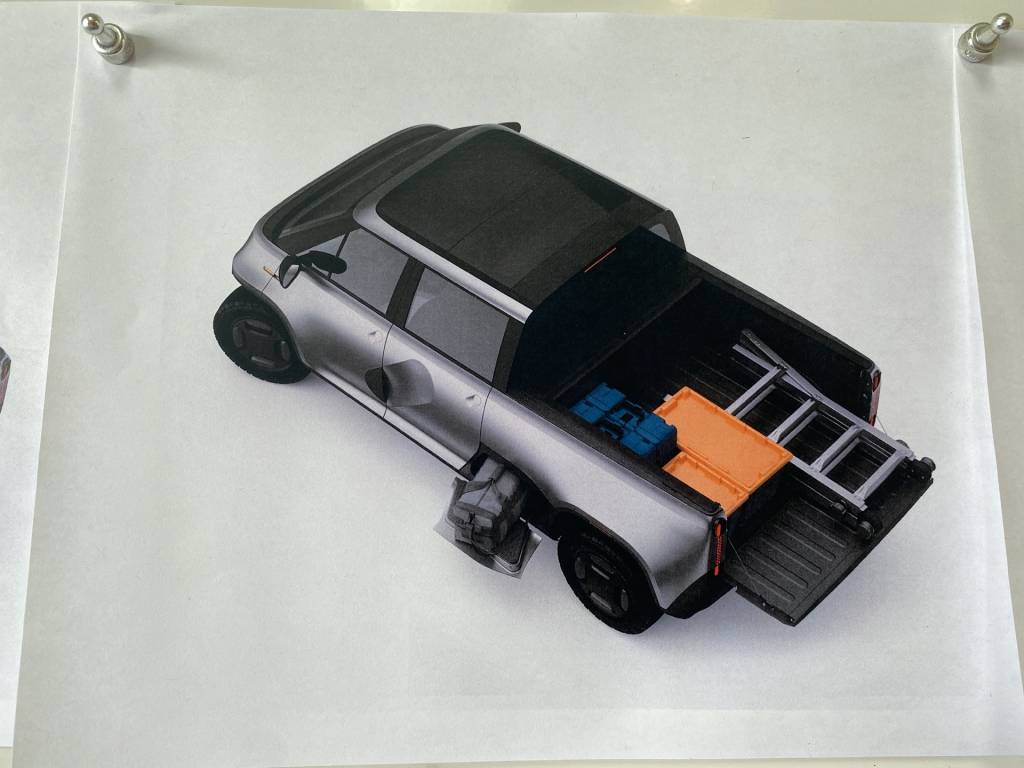

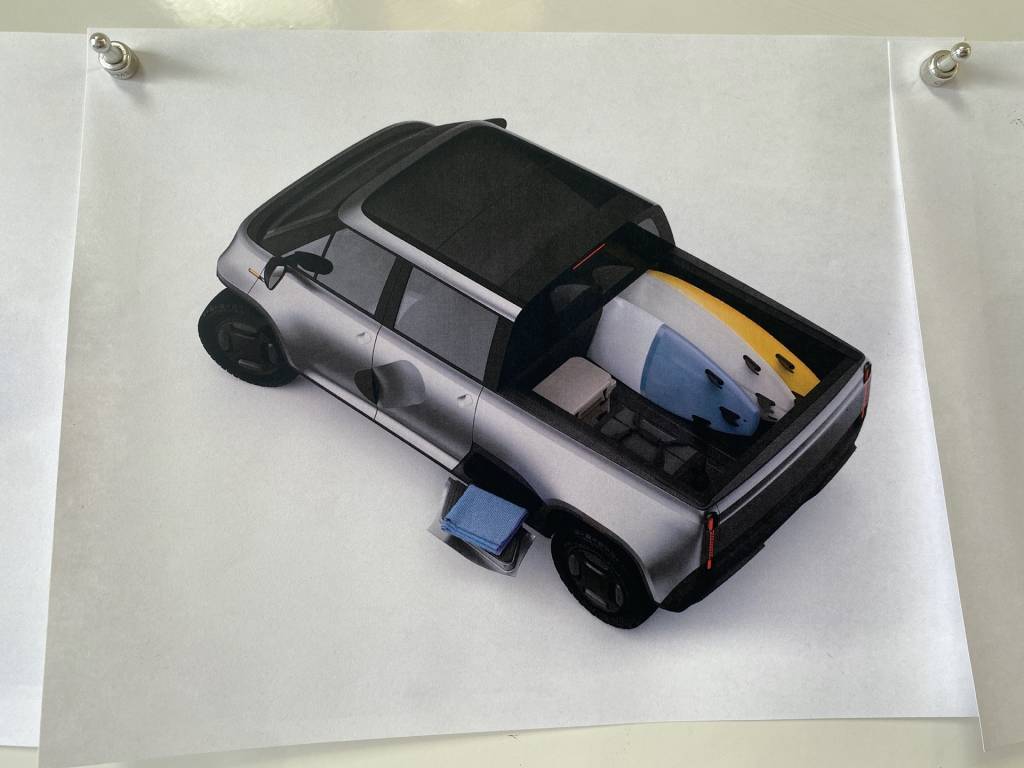

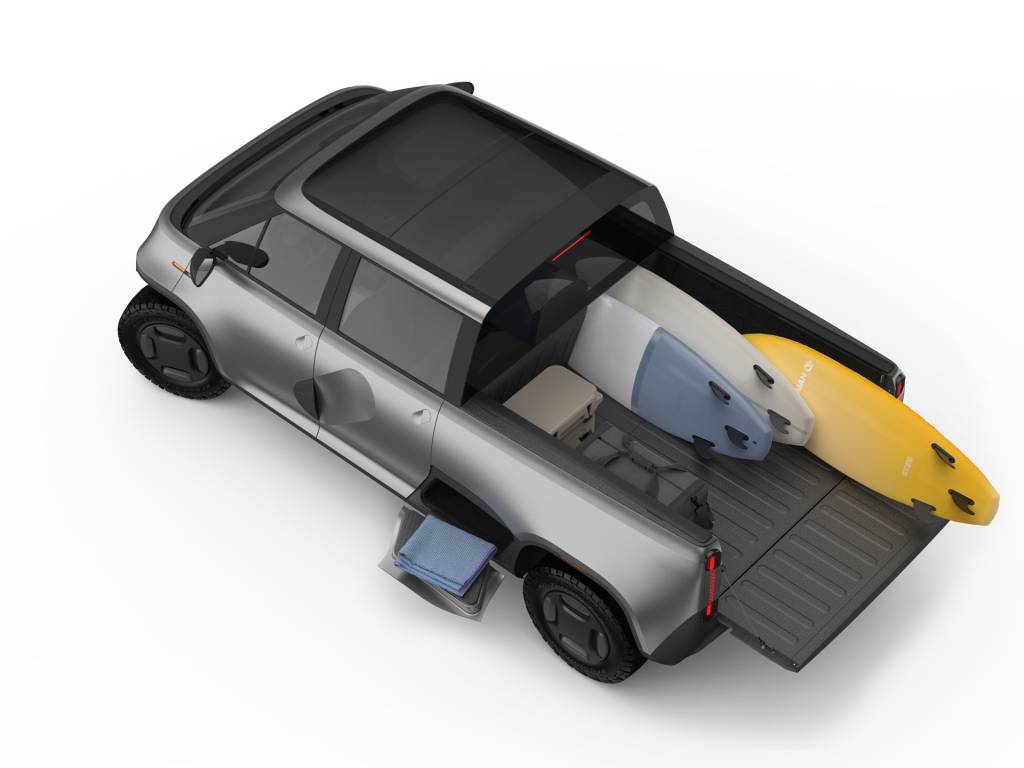

Telo says that with the midgate folded, its truck will fit 4-by-8-foot-sheets of plywood, a 9-foot surfboard, long ladders, and other long objects behind the front seat, with the tailgate up. All from a vehicle that’s far smaller than an F-150 Lightning, Rivian R1T, or Tesla Cybertruck.

If you’re wondering, a bit bewildered, how it all falls into place, that’s kind of the point. Not even renowned designer Yves Béhar, who has a resume of breakthrough products for Jawbone, Herman Miller, Sodastream, and Samsung, among many others, and designed this electric truck, could quite get his head around the idea at first.

“I said, ‘Wait, what, you can do all this functionality, of the Rivian, but in the size of a Mini?,” Béhar, a Rivian owner, recalled of his first conversation with Telo’s founders about the idea, at a preview event last week where City Dwellers was in attendance. The description of the product, its sizing, and performance all seemed impossible, he said, until he looked at the layout. “And you realize it is possible by challenging the status quo of the way cars are built, and how we’re still dealing with the legacy of the gasoline engine today.”

Telo, which gets its name from telos, for purpose in Greek, is indeed a purpose-built electric truck. The mission: Drop all the wasted space where the engine bay was and end up with a product that actually takes advantage of the freedoms that electric propulsion affords.

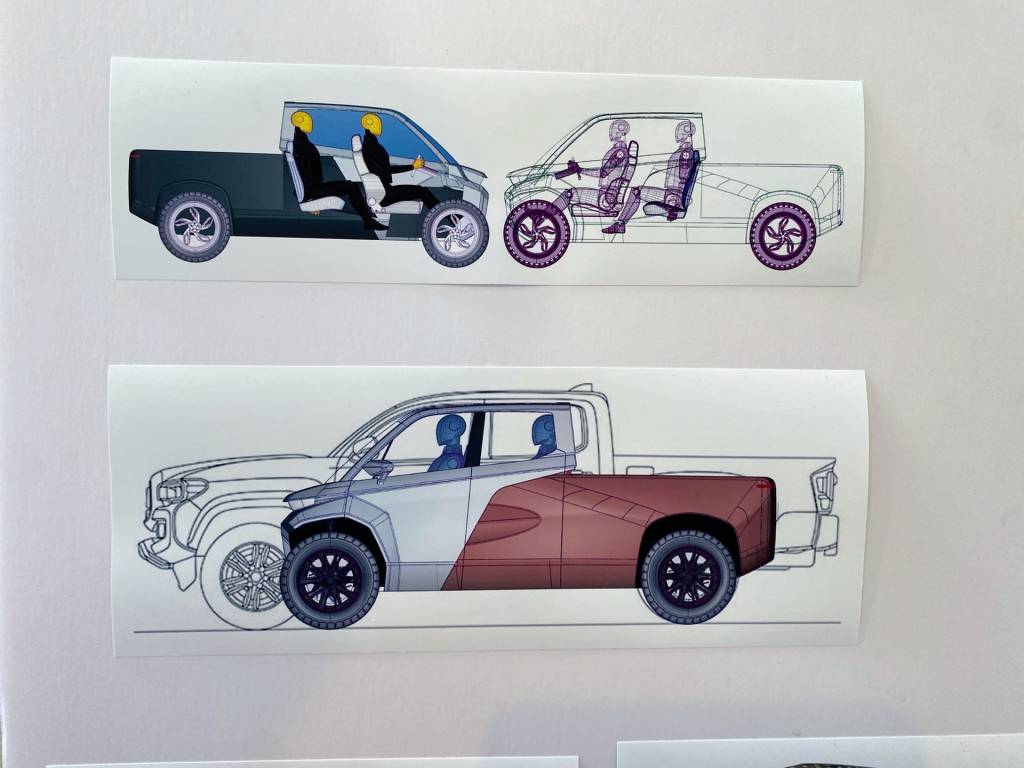

Telo truck vs Toyota Tacoma

What that means is a projected 0-60 mph time of around four seconds, a payload of 1,600 pounds, and a tow rating of 6,600 pounds—all while measuring one-third shorter than the Toyota Tacoma Double Cab. In keeping with Telo’s vision, it appears in profile that the third of truck that’s missing is the engine bay.

With about 500 hp combined from two motors, and all-wheel drive, the Telo will have a “quite large” torque rating that makes it well-suited to towing big loads.

As with any startup, many hurdles lie ahead, and the founders were straightforward with City Dwellers about how much of their vision is taking form and what remains to be done, with refreshing pragmatism combined with all the benefits of following in Tesla’s footsteps.

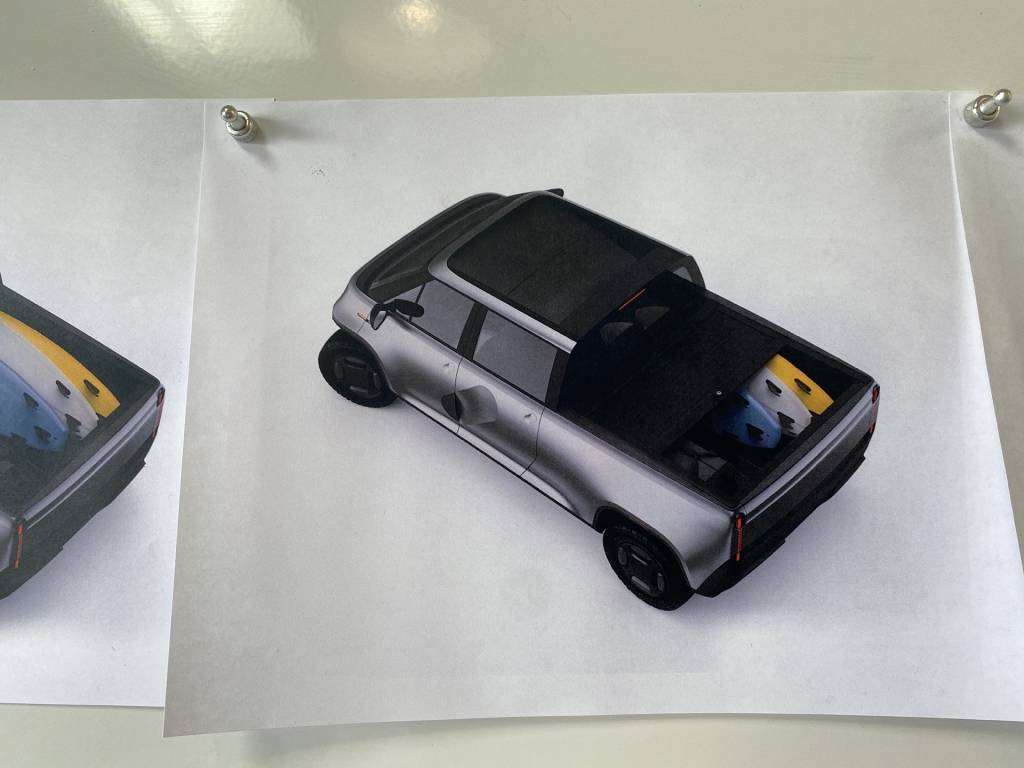

Telo truck (rendering)

The future of EV frunks looks less certain

But first: Why hasn’t anyone been doing this?

“I think the way Tesla has made loud cars sound slow, we’re going to make any car that has a nose feel old,” said Forrest North, who co-founded Telo and is the company’s CTO, who homed in on pictures of boxy pickup profiles on the wall. “Because why would you carry this giant thing in front of you?”

“It doesn’t help you drive; it doesn’t help with safety; it doesn’t help with anything really. And so but we’re just kind of stuck in this paradigm. It’s kind of like the tire on the back of the Oldsmobile fading out over time.”

North thought that as electric cars took off “there would just be an explosion of different vehicles,” and noted that he was surprised when vehicles didn’t change shape.

North has witnessed the electric vehicle revolution from a front-row seat. He was on the Stanford solar car team, and he landed an early seat at Tesla in 2005. In the many years since Tesla, he founded PlugShare and the electric motorcycle firm Mission Motors, and worked at FreeWire, among others.

Mission Motors Mission One electric motorcycle prototype

In 2019, North first joined forces with Telo CEO Jason Marks on a different electric motorcycle project. But just over a year ago they pivoted to a different passion project, the Telo truck, and brought Béhar in.

“The electric vehicle allows you to do all these configuration changes that no one’s really doing yet or popularizing,” said North. “So I really was disappointed that the automakers were making just bigger and bigger vehicles the same way.”

Marks now has a Toyota Tacoma that he appreciates for its utility, and North used to have a Ford F-250. But in the EV age, both of them set out to make a breakthrough product.

“We really set out to kind of rethink the electric vehicle footprint from the ground up,” said Marks. The startup sees the hood space as a relic of the internal combustion era, and doesn’t think buyers are really going to miss the frunk with a gear tunnel under the bed and other creative cabin storage.

Telo truck – buck on engineering chassis

Telo truck – buck on engineering chassis

Telo truck – buck on engineering chassis

Starting with a skateboard—and lots of carbon fiber

Telo’s original name after the pivot gives you an idea of where its intent was. Originally called Olley, it was named after Maurice Olley, one of the pioneers of modern suspensions and vehicle dynamics a century ago.

“We were really enthusiastic about suspension design, but we realized that it wasn’t really encompassing all of our vehicle brand,” mused Marks.

To that, with pre-seed money that Marks describes as “extremely lean,” the startup designed its chassis, modeled the dynamics, locked it in for the rest of the vehicle, and built a full engineering version of it from scratch. It has an independent rear suspension to allow a larger bed, and Marks says it allows good cornering performance for its eight inches of ground clearance. Tires are 27-inch off-the-shelf off-road tires, because there’s a wide range of possibilities, from off-roading to low-rolling resistance.

The chassis is essentially a skateboard, and bodies bolt directly to the chassis. It’s building the vehicle a bit like Aston Martin or Lotus, with composite carbon components at the four corners, aluminum extrusions. Telo plans to build much of the rest of the vehicle of carbon-fiber-reinforced plastic (CFRP), with some of the structure beneath made of it, too.

All the CFRP will cost less than $1,000 altogether, Marks said—an indication of the commoditization and ubiquity of what was once considered exotic even at the time of the BMW i3 launch, for instance. “Carbon actually helps us shrink the vehicle, because it allows them to make things like wheelwells structural components for mounting the struts,” Marks said, adding that carbon fiber gives the company a roadmap to becoming more sustainable, with recycled and plant-based possibilities nearing viability.

Telo truck (rendering)

350 miles from just enough battery

“A 10,000-pound electric pickup is not the path to efficiency…your 229-kilowatt-hour battery pack is not going to get you to a sustainable future,” said Marks—clearly referring to the Ram 1500 REV.

Within the chassis and just below the floor will be one of the thinnest battery packs in a passenger vehicle—at a capacity of up to 106 kwh, allowing an estimated EPA range around 350 miles..

Telo says that the key to the packaging is keeping the battery as low and thin as possible—within a 10-cm height, total. That gives Telo 10 inches of ground clearance from a vehicle that’s only 66 inches tall overall, and it helps reduce the frontal area.

Telo truck

Telo’s battery pack, which achieves somewhat higher energy density than current Tesla models, according to North, has all of its connections on one side, while it extracts heat off the other wise. It’s designed to be laser-welded “in a single shot,” with surface-mounted fusing and thermistors. For now Telo plans to use totally off-the-shelf 2170 cylindrical cells—so far, the latest low-impedance cells from Samsung. North says that once the company gets big enough it might try to tune chemistries with a supplier.

The pack will be liquid-cooled, although the founders say that they’re taking some of what’s been learned in the semiconductor world and applying it to battery cooling—with a hint that it might actually simplify battery manufacturing.

That said, the company is looking at a 20-80% charge in 20 minutes—with native NACS support for Supercharging their interface of choice.

Telo is doing its own battery pack partly because the height of the battery pack is so important in packaging. It’s one of a cascading series of interrelated factors, Marks explained, because it allowed them to shrink the frontal area and then optimize the efficiency of the pack itself, arriving at a vehicle ”as efficient as some of the best, class-leading electric crossovers on the market.”

Telo truck

Telo truck

Telo truck

Telo truck

Safety in the skateboard

The battery pack is also a structural component of the vehicle chassis, and a key safety item. “The seats and everything actually mount to the top plate of the battery panel,” according to Marks. That will enable the company to complete homologation of the core of the vehicle, allowing reconfigured versions—with less redundant testing needed for other potential body styles, like a van.

If you can pass FMVSS 208, the core standard for occupant crash protection, with the chassis itself, and you have an easy-to-manufacture platform, then multiple body styles might be easily contract-manufactured, explained Marks. A van, for instance, says Marks, would have a sliding door in its body, but “it’s all contained on this exact same chassis.”

The company consulted with computational fluid dynamics (CFD) experts, who see a 0.30 coefficient of drag as possible, but they’re not there yet. A novel channel through the lower portion of the door will pull airflow through the front wheelwell and kick it up to meet the flow off the roofline.

The idea of wheel slats hasn’t been totally dismissed yet. “We’re obviously going to iterate on our design before we release it to the public, but it won’t be far off from what you’re seeing right now,” said Marks.

Telo founders Jason Marks and Forrest North, with designer Yves Béhar

Core competencies, then contract manufacturing

Mechanically, many of the other components in the Telo truck like motors, transaxles, and power electronics will be off the shelf, from suppliers, while Telo is saving its own development resources for the safety technology, the battery technology, the design, and the packaging.

North says that many of the final decisions the company makes about components like motors and inverters will be for packaging, not ultimate performance.

Marks knows exactly where the sensors will be and how they’ll be used. He oversaw the development of testing systems for driver assistance systems at National Instruments, worked on lidar at the semiconductor level for what became continuous wave frequency modulated lidar, and then worked on radar and lidar together.

Telo Trucks CEO Jason Marks, with off-the-shelf motor candidate

“Imaging radar has only become really useful and cost effective and packable on a semiconductor level in the last year and a half,” he said. “It’s actually surpassing lidar in a lot of the cases, in terms of the fidelity you’re getting, at the price point you’re getting it.

Marks sees it as a safety issue for those outside the vehicle, as pedestrian fatality rates are far higher relating to large trucks than for other vehicle types.

For the cab-over design, the interface and head-up display will help drivers keep the right following distance, and the interface and suite of active safety systems are being designed to be a constant companion, not something you’re repeatedly engaging and disengaging.

Telo Trucks H-point model

Fitting five adults in the Telo truck

Considering all the detail on the chassis and battery pack, Telo is still at the very early stages in designing cabin details, and the full-scale example I saw last week at Telo’s garage was a design buck on top of a true engineering chassis—a fiberglass-on-foam-core replica that’s been resin-sealed, primered, sanded, and wrapped. A childhood visit to Louis Tussaud’s Waxworks came to mind.

With the help of digital modeling and a wooden physical H-point model, built last summer by an intern, the son of Tesla co-founder Marc Tarpenning, Telo knows its cabin dimensions work—and that it’s slightly larger in all dimensions than a four-door Toyota Tacoma interior, and has considerably more headroom. At 6-foot-6, I actually fit behind another writer who stretches 6-foot-10, with the front seat back all the way.

The most jarring thing is how far forward in the vehicle the driver sits. There’s 18 inches of mechanical crumple, which Marks points out is the same as a Smart Fortwo and not all that much shorter than the 24+ inches of existing compact crossovers with engines under the hood.

The Telo truck will have a midgate setup that’s a key enabler for its versatility. “By opening up inside, you get this advantage, which frankly I used to only get with hatchbacks, where you can put all of the seats down and finagle stuff in,” said North.

The bed pitches slightly downward toward the front, which helps both keep items in place and allows a little more bed space around the motor assembly.

Telo CTO Forrest North

Tesla’s birthplace, and some big names

This all came together at Telo’s San Carlos garage, a tucked-away space in a quiet, semi-industrial neighborhood of San Carlos, just a few blocks from Tesla’s original Commercial St. location (and later Bing St. location).

The company currently consists of just five full-time employees plus a multitude of contractors and consultants. Its senior advisor is Andy Palmer, the former CEO of Aston Martin and the executive at Nissan that helped get the Leaf to production. Former Tesla engineering executives Dorian West and Dave Lyons are also advisors.

“We wanted to surround ourselves with people that really have done this before and know what they’re doing,” said Marks. “Because what we’re doing is really kind of redefining the packaging, the design, the batteries, the safety, but we wanted to use a lot of knowledge that exists in the automotive world to bring things to market; we’re not just gonna completely ignore that.”

Regarding the interior, Marks has ideas. “We want haptics, we want buttons AND touch, and we want it rugged yet approachable,” he summed, to match the exterior personality.

Telo truck (rendering)

Who will buy this electric truck?

Telo sees its customers as ourdoorsy singles, couples, or those with small kids, living in or adjacent to dense urban areas—especially in the type of communities affected by California’s SB13 and other such rules around the country aimed at increasing urban density. They tend to create more duplexes, triplexes, and ADUs in place of garages, while downsizing driveway parking. And that tends to make streetside parking scarce and small.

The idea is to give those urban-dwellers a vehicle that’s easy to park, yet one that can get away for adventures on the weekend, with space to stow gear for snowboarding, skiing, or surfing, and have enough range to do so—or, likewise, the easy maneuvering capability to run to the gardening or hardware store.

For example, the front pillar was pulled back in order to afford such a clear view out for maneuvering.

“We want to see this be kind of like the F-150 for the city,” said Marks, noting that it sees a huge demographic in municipalities and electricians, plumbers, contractors, and utility companies. “And so we’ve started the conversations with those companies that are actually buying the vehicles for those particular areas.”

Telo truck (rendering)

Telo truck (rendering)

Telo truck (rendering)

What’s most noteworthy about the design, perhaps, is that it makes no nods to vehicles of the past. What’s small doesn’t also have to be cutesy-retro, and it’s a refreshing twist that this is not.

Béhar said that in a project, there’s always an argument to make it kind of like the legacy thing because that’s what will help with commercial success. “And what I’ve discovered is actually just the reverse; I’ve discovered that it doesn’t mean you’re going to be edgy. “You don’t have to use fake signals for people to understand that this is a valuable next-level-innovation product.”

“It communicates a functionality that’s friendly and approachable—which we got away from a long time ago with pickup trucks,” he added to City Dwellers, referring to the semi-influenced grilles that started with the ‘90s-era Ram.

Telo truck (rendering)

What’s next

While it’s looking to build the battery pack itself, Telo wants to use supply chains for the rest of the vehicle platform, and a contract manufacturer for assembly.

It aspires to be a mid-volume maker first, in the 10,000- to 100,000-vehicle a year zone first, becoming a high-volume manufacturer eventually and building its own factories when production exceeds that.

Telo is hoping it can assemble the vehicle in North America, leveraging North American battery supply and taking advantage of EV tax credit provisions.

So far it’s only raised pre-seed financing from angel investors and a small amount from venture capital, and it’s engineered the chassis with that small amount. With this reveal of the design and chassis it wants to demonstrate legitimacy and that consumers actually want this, said Marks.

Telo truck (rendering)

With many details falling into place, it’s now reaching out for hand-raisers—for an initial version of the truck that is targeted for $49,999, not including eligible incentives. And for that, it’s seeking $152 for pre-orders, which is a nod to the length of the vehicle.

Part of it at this point is simply verifying that the demand for such a product exists, Marks confessed. The two founders were very encouraged by the success of the Maverick hybrid pickup, also a smaller truck albeit one with a conservative design. The level of interest in Aptera might also be seen as a good indicator.

Telo will need to raise hundreds of millions of dollars to see its trucks all the way through to production. It hopes to have a drivable vehicle with an interior by the end of the year. Following that, it will go through the homologation process, then a mostly virtual validation process, then durability testing—also through a contract supplier.

With its emphasis on design first, and the focus on the battery pack and safety, it seems that Telo has its priorities in the right order to shake up the field. Let’s see if people are ready to take the truck new places.