Racing tech may bring efficient in-wheel motors into more EVs

Elaphe and McLaren are partnering to marry the former’s in-wheel motor tech with the latter’s racing expertise.

At the recent 2023 CES in Las Vegas, the two companies announced an “in-wheel propulsion system” using Elaphe’s in-wheel motors and inverters from McLaren Applied Technologies to create “highly efficient and hyper-responsive electric vehicles,” according to an Elaphe press release.

Elaphe-developed in-wheel motors are at the core of some of the most eagerly anticipated super-efficiency vehicles—like the upcoming Aptera. With in-wheel motors, Lightyear has claimed the most efficient production powertrain in the world for its Lightyear 0 solar-assisted EV.

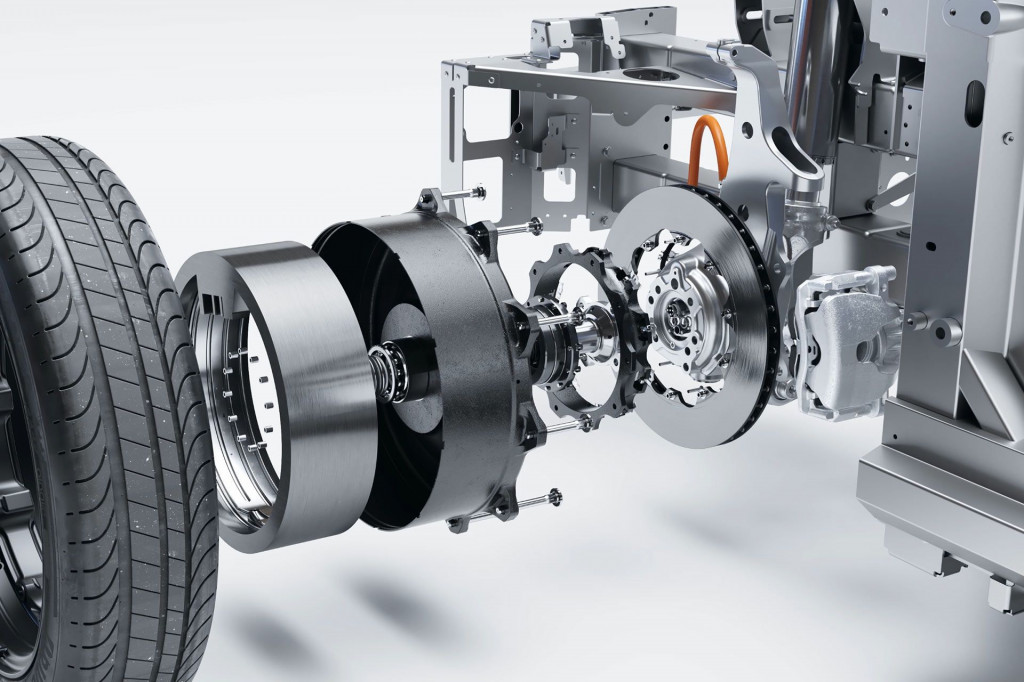

Elaphe in-wheel motor for Lightyear 0

Lordstown Motors in 2020 announced a deal to license Elaphe’s in-wheel motor tech for its Endurance pickup truck. It still stands out as the only company that is using in-wheel motors for a conventional truck rather than an efficiency-focused vehicle like the Aptera and Lightyear.

Issues like the added unsprung weight of a motor mounted in the wheel hub have limited the number of applications for in-wheel motors, but Elaphe hopes the addition of the McLaren unit’s racing tech will help broaden their appeal.

McLaren Applied Technologies has designed inverters for Formula One and Formula E, as well as the McLaren P1 plug-in hybrid supercar that debuted in 2012, according to Elaphe. McLaren also competes in F1 and (as of 2023) Formula E as a factory team, but the racing, road-car, and applied-technologies divisions are all siloed within the company.

2022 McLaren MCL36 Formula One race car

The powertrain developed in partnership with Elaphe will use McLaren’s newest IPG5 inverter, an 800-volt silicon-carbide unit that can deliver efficiency of up to 99%, Elaphe claims, with the in-wheel motors themselves claimed to have demonstrated up to 97% efficiency. Together with its motors, that will help provide “best-in-class long-range cruising efficiency and unmatched vehicle controllability, with a torque response five times faster compared to existing systems,” according to the company.

This won’t be the first example of racing experience informing EV road-car development. Lucid’s battery division Atieva served with McLaren Applied Technologies to power Formula E racing for several years, then applied its Formula E battery expertise to the Air luxury sedan.