Charged EVs | Solar-powered off-grid EV charging stations offer surprisingly attractive cost advantages

- By cutting red tape and avoiding costs for construction and electrical work, combined with free solar energy, Beam Global says its EV ARC systems can offer customers a lower total cost of ownership compared to grid-tied charging stations.

- In almost every instance, Beam says its customers’ savings on construction and electric work exceeds the cost of the EV ARC, which starts at $59,400.

- Over the past 10 years, the company has deployed hundreds of EV ARCs, which represent a growing list of incredibly compelling use cases, including otherwise impossible charging locations.

- EV ARCs can be deployed with Level 1, Level 2 or (using 4 or more units connected together) DC fast charging.

Q&A with Beam Global CEO Desmond Wheatley

During periods of rapid technological change, it often turns out that certain new products have highly useful applications that few—perhaps not even their inventors—originally foresaw. This may well be the case with the EV ARC, a solar-powered off-grid charging station made by Beam Global.

When we first covered the company, which was then known as Envision Solar, back in 2013, we immediately saw that its product would be handy for events, disaster relief and other applications requiring a stand-alone energy source that could be set up quickly. Since then, as charging stations both public and private have proliferated, a major challenge has emerged: installing chargers often involves site preparation, trenching, upgrading utility service, permitting and regulatory approvals…the list goes on and on. Dealing with these requirements can end up costing more than the price of the hardware, and can cause delays of months or even years. The EV ARC neatly sidesteps all these hassles, and once it’s installed, it provides energy at no marginal cost, almost as a bonus.

The EV ARC is not just a portable charging station—it’s an off-grid solar power system and stationary storage device that offers EV charging as an option. Portability is one feature—the unit is transported on a custom-made trailer, and one of the company’s “deployment experts” can set it up in as little as a few minutes—but the system can also deliver multiple benefits in permanent installations.

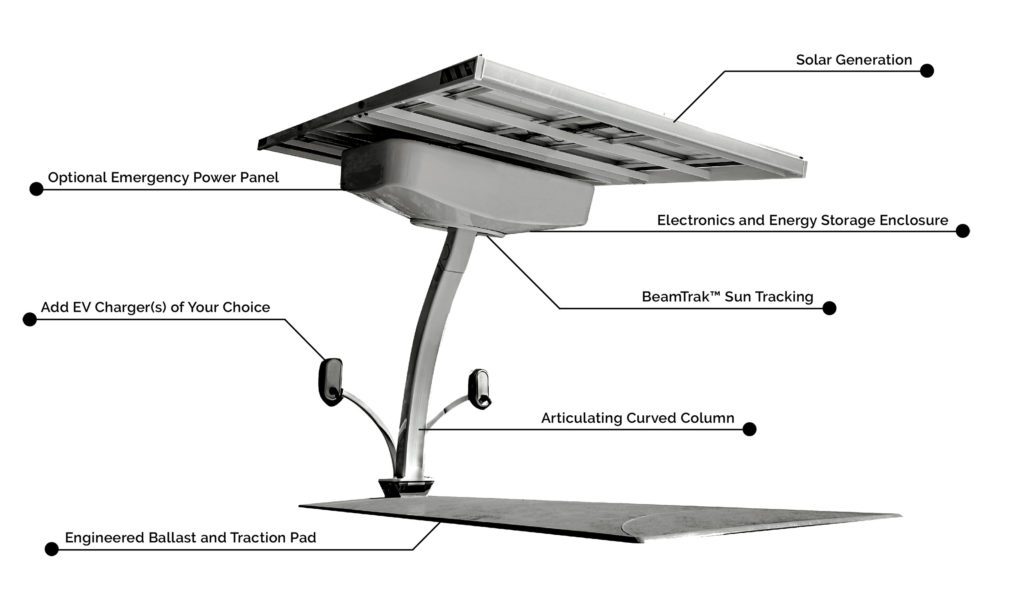

The EV ARC features a 4.3 kW sun-tracking solar canopy, and battery storage options of 22, 32 or 43 kWh. It can be equipped with EV chargers of any brand. The whole thing fits in a single standard-size parking space.

Charged recently spoke with Beam Global CEO Desmond Wheatley, who has been with the company since 2010, about the surprisingly wide range of benefits of the company’s EV ARC and Solar Tree systems.

Charged: We’ve been covering your company for some years, but it used to be called Envision Solar.

Desmond: It’s exactly the same company, but we rebranded a couple of years ago. And the reason we did that is because Envision Solar was a very misleading name for us. Although we do use solar as one source of energy to power our products, it was a bit like calling Casio “Casio Solar” because they have a solar-powered watch. We make products that happen to use renewable sources of energy as opposed to connecting to the grid for the primary source of energy. I like Beam much better—a beam of energy, the structural beam.

Charged: When did you start selling the EV ARC?

Desmond: It’s been ten years, and obviously we were a little bit crazy making a solar electric vehicle charging product ten years ago. There were only about four EVs (not just four models—I mean four vehicles) on the road at the time, but I was convinced that electrification of transportation would take place. I was definitely too early to the party. However, that party is really kicking into gear now, and all of the things that led me to come up with the EV ARC—my knowledge of what it takes to build infrastructure, go through permitting, environmental impact and also the understanding I had of the utility grid’s limitations—were what led me to build the product in the first place.

For the first eight years of our existence, it was hard to get people to really grasp that. Now they’re understanding it with a gusto all the way from the halls of power in Washington DC to corporate offices across the country.

Charged: The more I read about your company, the more I’m struck by the many different applications and use cases.

Desmond: With a couple of beers and a couple of hours, we could literally write a list two or three hundred items long.

Charged: For example, one of your customers has a site where they’re not allowed to do any digging because of hazardous waste. I would never have thought of that.

Desmond: That’s, again, a lesson hard-learned by me in my past. I built lots stuff in my lifetime, and there have been some instances where I was unfortunate enough to encounter subterranean hazardous materials. And the thing is, you end up owning it. In California, you end up having to clean, do remediation, and take all the spoils to Kettleman City [the site of a hazardous waste facility]. And that could be an end-of-project type of deal.

“At just about every airport in the country, you do not want to be digging up the asphalt because most of the airports were built back in the twenties and thirties when the way you dealt with hazardous materials was to bury them under the concrete.”

But the thing is, we knew that they would need EV charging in these types of environments—brownfield sites, nuclear waste sites. And frankly, at just about every airport in the country, you do not want to be digging up the asphalt, because most of the airports were built back in the twenties and thirties when the way you dealt with hazardous materials was to bury them under the concrete. So, the fact that we are able to deploy without digging for foundations or trenching or anything else means that we’re an ideal solution for those types of environments.

Many airports across the country will have a whole host of reasons why they do not want to get into that type of construction project. One of those would be the potential for encountering hazardous materials, but there are many others. Of the 20,000-odd airports that there are in the US, about 15,000 of them are the smaller general aviation airfields, and they simply do not have sufficient electrical circuitry to provide charging for terrestrial electric vehicles, far less for the wave of electric aviation that’s coming.

We were able to help set the world record for the longest flight of a production electric aircraft last year, and the simple reason that we were able to do it where nobody else could was that we deployed charging infrastructure as this aircraft island-hopped up Central California. Nobody else can do that. And in fact, when we first contacted the airports and said we want to break this world record, they all said no, because we don’t want anybody digging, we don’t want the construction project, plus we don’t have enough capacity on our electrical circuits. And we said, we’ll send you a video and you’ll see why you don’t have to worry about any of that stuff.

The company that built the plane is called Pipistrel. They have what certainly was at the time, and probably still is, the world’s only production electric aircraft, meaning you could buy one. This is an off-the-shelf product—fantastic, by the way. We did [the record-setting electric flight] in conjunction with them and with another organization in central California that’s trying to rejuvenate these general aviation airports. California’s covered in them, and most of them are becoming disused because no one can afford to keep aircraft in the air. But the good news is, while it costs $40 to $50 an hour to keep a small plane in the air, the electric aircraft costs $4 an hour—and even less than that, if you fuel it with sunshine as we did.

Charged: I understand you have over a hundred US municipalities as customers. What are they using the EV ARC for?

Desmond: There are three primary use cases for it. The first one is fleet charging, and this is not just municipalities, this is the federal government, US Marine Corps, many others. They’re charging their own fleet vehicles. And when we talk about fleet, of course that’s a very broad group. In New York City, the police department, animal welfare, you name it—every department that the city has, they’re now moving to electric vehicles, and they need charging infrastructure. In New York City, it takes an average of 24 months to put a grid-tied charger in the ground, by the time you go through environmental impact, permits, electrical work, everything. We do the same thing in less than one hour.

“In New York City, it takes an average of 24 months to put a grid-tied charger in the ground, by the time you go through environmental impact, permits, electrical work, everything. We do the same thing in less than one hour.”

Beyond that, of course, in New York, like many other jurisdictions, there is a lack of capacity on the utility grid. This is why in August, when everybody turns up their air conditioning, ConEd turns the power off, because they do not have enough electricity to cover the current base load. As you electrify transportation, that problem’s going to become much more acute. Our products, of course, don’t require the grid, and therefore we’re able to deploy in New York without having capacity problems.

And then finally, New York is a target for terrorism and all sorts of other things, and the grid is a target. New York very sensibly wants charging infrastructure that will continue to charge their vital fleet vehicles during any type of grid failure, whether that’s caused by a hurricane or because someone hacked into the grid or because terrorists knocked out a few substations, and our products solve that problem.

So that’s fleet. Then the next use case is workplace charging. We do that both municipalities and the federal and state governments, but also for corporations like Google, Johnson and Johnson and many others.

Then the third type of charging that the municipalities are offering is public charging. They’re trying to encourage people to clean up their carbon footprint, but they also want to encourage people to come into the city and spend money. So, if you provide EV charging, you get that EV driver who’s coming in pollution-free. EV drivers today are generally more affluent, so there’s more to spend.

“Because people have never done this before, they don’t understand that it’s going to take them a very long time to go through the permitting and construction and electrical work. We solve that problem for them.”

Charged: So, the reason for choosing the EV ARC instead of a grid-tied charger is because it can be installed so much quicker and easier.

Desmond: You’re absolutely right. The rapidity, the ability to deploy the infrastructure when you want it, not two years later when you’ve gone through planning and had the utility and everybody on board. That is absolutely huge. Many of our customers today, and this is increasingly the case, are taking possession of electric vehicles and they don’t have EV charging infrastructure. So they’ve got a lot of urgency. And because people have never done this before, they don’t understand that it’s going to take them a very long time to go through the permitting and construction and electrical work. We solve that problem for them because we can provide charging for them immediately. There’s a lower total cost of ownership too, and that’s driven by the avoided costs associated with construction and electrical work.

We have hundreds and hundreds of locations deployed, and in almost every instance, the avoided cost of construction and electric work is greater than the cost of our product. So from day one you get [savings], because you didn’t spend money digging trenches and pouring concrete and doing all that sort of stuff. And then of course you get a lifetime of free energy. If you avoid the cost of construction and electric work, you don’t even need to amortize the equipment anymore, and your cost of energy is zero. Think about that. Now you’re putting fuel into your fleet vehicles as a zero unit. That’s the first time that’s ever happened since horses, when the unit of energy was blades of grass, and even that wasn’t always free.

“In almost every instance, the avoided cost of construction and electric work is greater than the cost of our product.”

Grid vulnerability is increasingly on people’s minds. We have more blackouts and brownouts today than we have had at any time in our history, and yet we’re more reliant on electricity than we’ve ever been. And then finally, capacity. The grid itself has nowhere near enough capacity to electrify all of transportation. Transportation consumes something on the order of 29 terajoules, and I think the grid delivers something on the order of 12 terajoules. So you can see right off the bat, there’s a huge imbalance there.

Even though EVs are more efficient, there’s nowhere near enough power on the grid. But it’s not just at the grid level, it is also at the substation level and even at the lot level. We have customers, for example, who have done the right thing—they’ve already installed grid-tied EV chargers, then more EVs come to their sites, so they need to put more chargers in. And they call their contractor and say, “Okay, you put 15 chargers in for me before, can you put in another 15?” and the contractor says, “We can’t do it, because you’ve already used up all your available circuit capacity on that site.” Most people don’t understand that electricity’s not just infinite, you can’t keep plugging more and more stuff into it.

So then that customer is faced with either an incredibly expensive circuit upgrade—transformers, everything else, if that’s even possible. Or they’re going to go to the utility to upgrade at the substation. And of course, that only works until all the substations have too much capacity. So there’s a whole bunch of capacity reasons customers come to us. They don’t have to worry about any of that. There’s no planning, no permission. It’s like Lego—if you want more, just add more blocks.

Charged: What’s the price of one EV ARC?

Desmond: They start at $59,400. And remember that’s an all-in price, no construction, no permit process, and you’ll never get a utility bill. The average selling price is probably about $65,000. And the difference is that we put differing levels of battery storage in the products depending on what the customer’s needs are. Some customers need more battery storage than others. Our pledge to our customers, and we’re very proud of this, is that we will never sell them something that is more complicated or more expensive than they need. We try to sell them only the battery level that they need, because batteries are really expensive.

So, let’s say average selling price is $65,000. And again, in almost every instance where we’ve deployed across the US and even a little bit internationally, that was less than the cost of trenching, concrete work, planning, permitting, electrical infrastructure and everything else that would’ve been required to put the chargers where we were deployed. And then the unit of energy thereafter is zero.

“We don’t get deployed where the grid is available—we get deployed where people actually want charging. And those locations are always much more expensive to [electrify] than the ones where the grid is available.”

It has to be said that you can deploy EV charging less expensively than that. On a typical building, maybe there is an existing electric circuit which is close to a wall on the other side of which is a parking space. And in that case, all you really have to do is drill a hole, some minor electrical permitting, minor electrical work, and you’ve got an EV charger. That might exist in one or two locations on your property, but that low-hanging fruit quickly gets eaten up, and now you’re digging trenches and going through the landscaping and whatever else. With us, we don’t get deployed where the grid is available—we get deployed where people actually want charging. And those locations are always much more expensive to [electrify] than the ones where the grid is available.

Charged: Your web site says the EV ARC is available with a Level 2 AC charger that can power up to 265 miles of EV driving per day, or with a DC fast charger that can power up to 1,100 miles per day.

Desmond: In fact, we do all three charging levels. Level 1 [120 V AC] works terrifyingly slow if you’re used to the gas station model, but many of our fleet customers drive less than 20 miles a day. In fact, some of the federal customers drive a lot less than that. So you can plug them in and charge them really slowly, but during five or six hours, they’ll pick up all the daily range replenishment (we call that DRR) they need. In that instance, we’ll sell an EV ARC with six chargers and plug in six fleet vehicles.

Eight out of ten commuters in the US drive less than 24 miles for their round-trip commute. So, we can plug six employees into a single EV ARC in a single parking space with no grid connection, and all of them will get their DRR while they’re parked there, or at least their commute replenishment. We also do Level 2 [240 V AC], and in that instance, we usually put one or two Level 2 chargers on an EV ARC.

Then finally, we do DC fast charging, and the way we accomplish this is not with one EV ARC but with four of them. So for example, at a rest area we’ll deploy four EV ARCs. They are all interconnected with an above-ground pre-engineered interconnection. Again, there’s no construction, permitting or electrical work. Then we’ll connect a DC fast charger, and we use all four of the EV ARCs, all of their generation and all of their storage, to provide that much higher charging rate, and more miles of course.

There are also some very interesting things from a technology standpoint that keep happening. First of all, our product keeps getting better. Just last year, we announced a 12% increase in the energy delivered from our product because our engineers keep making it more efficient and essentially converting more sunlight to electricity, storing that electricity and then delivering it into a vehicle than before. The constant improvements in our products mean that the 265 [miles per day] used to be 240, before that it was 180, and so on. When I first started doing this 10 years ago, believe me, there were nowhere near this good.

But there’s another factor in the industry which is really helpful as well—electric vehicles themselves, not surprisingly, are becoming more efficient. When I first started driving an EV 12 years ago, I was getting about 2.5 miles per kilowatt-hour. Today I can routinely get 5 miles per kWh. Now, I know how to maximize range, but it’s not driving slowly—I’m European, I’ve got a lead foot. But there are even car manufacturers now, like Lucid for example, I think they just announced 5.6 miles per kWh or so. The technology’s improving. So, if we tell you that an EV ARC will provide you 265 driving miles and we’re using 3.5 to 4 miles per kWh [as a benchmark], but in fact your vehicle is getting 5.5 miles, clearly the EV ARC is going to produce a whole lot more miles for you.

Charged: Tell me about disaster relief, because we just had a big hurricane here in Florida. I was down in Lee County a whole ago, trying to help out. I understand that you have three EV ARCs deployed in Florida right now.

Desmond: Yes. The fact is, whether we like it or not, these types of events are becoming more frequent and more severe, so we made some significant improvements to the EV ARC over the last couple of years. Previously, our electronics and our battery storage were mounted at ground level in an enclosure, which is common in the industry. We have migrated all of that into the canopy, which tracks and follows the sun, so now anything that matters on the EV ARC is 9.5 feet above grade. We can survive an inundation of 9.5 feet without any ill effects to the product at all.

“We also have emergency power panels built into the units and those are also 10 feet above grade. So first responders, EMS, police can come and connect life-saving equipment to that emergency power panel.”

Furthermore, the product is currently independently rated for 125 mph wind speeds, and we’ll soon be rated for 150. But here’s the good news: We were in the Caribbean for Irma and Maria, and our products in those storms survived Category 5, 185 mph winds. It’s fantastically robust.

In disasters, the first thing you lose is grid power. We also have emergency power panels built into the units and those are also 10 feet above grade. So first responders, EMS, police can come and connect life-saving equipment to that emergency power panel—not just charge their vehicles, but also take power off the units to do other things like running ventilation, medical equipment, radios and other things.

This is not theory. This has taken place in several instances where first responders and others have actually used EV ARCs during critical events. Most famously, the City of Oakland used the EV ARCs that they had deployed at their offices during the height of COVID. No one was going to the office, so the EV ARCs were underutilized. They moved them to COVID emergency medical centers and they got rid of the diesel generators—they used the EV ARCs to power the emergency centers and also charge their vehicles on those sites.

So it’s a very real application. I always joke that we’re a bit like Clark Kent. We’re sort of boring seven days a week, but if the shit hits the fan, the EV ARC pops into the phone booth, spins around and comes out as Superman and becomes even more valuable.

Charged: Any interesting new products coming up in the future?

Desmond: We’ve got our streetlight replacement product, which is going to allow curbside charging. You take out the existing streetlight and replace with our product that has a light wind generator on the top of it, and a tracking solar array, and the column of the streetlight is full of our batteries (we make our own batteries and electronics). So we’ll be able to provide a meaningful EV charger on the curb. If you think about all the vertical cities, New York, San Francisco, Chicago, and then Asia and Europe, they don’t have big flat parking lots like you have in Florida or we have in California. Tthis will allow for curbside charging, but without doing any type of civil work or electrical work on it. It leverages the windmill, the solar and the streetlight circuit. We combine all three into our batteries and then we provide charging from that. We should be producing those next year.

And then right after that, we have a patented product which is designed to recharge drones. We think there’s going to be a big increase in the use of drones for package delivery and also military applications. The problem with drones is that they’re limited by their range and payload capacity, which is two ways of saying the same thing. They have to run home to recharge. In this instance, we will deploy networks of these things, and then the drones can island-hop without ever coming home. And we even have a modernized version of that in the patent. The US is launching drones off submarines, and now the submarine has to surface [to recharge the drones]. Our product will float out there, GPS-stabilized, and drones can refuel and exchange data with the submarine.

Charged: You make your own battery packs?

Desmond: We do. That was a very important thing to us—the safety, the energy density, and chiefly our ability to make batteries in any shape that we want to. Most people are making batteries in squares and rectangles, and that’s just not very useful when you’ve got to try and fit batteries in drones, in submersibles, in medical devices, in stationary devices…all sorts of things. It’s really important to maximize the efficiency of the real estate that you’re using, and sometimes that means not using a standard block-shaped battery. We are able to do that with our thermal management material that essentially is pretty unique to us, and we have lots of good patents on it.

Charged: And the EV ARC is charger-agnostic. You can use any kind of charger hardware and any charging network. Right?

Desmond: Exactly. We don’t compete with those guys. We support them. We enable them.